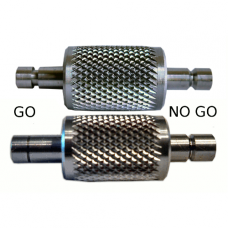

The small Swage Gage works for both small rifle and small pistol. The large Swage Gage works for both large rifle and large pistol. One side of the gauge is the "GO" side and the other is the "NO GO" side. The GO side is marked with a square groove, the NO GO side is marked with a V shaped groove.

The GO side should enter easily and the brass should not tend to stick on the gauge if you turn the gauge over and shake it (assuming pockets are relatively clean of brass shavings and residue). The inner lip of the primer pocket should appear shiny. When inserting the GO side you should not feel any "catching" or resistance. A good deep swage indicated by easy insertion of the GO side will cause the least priming problems.

The NO GO side may enter very slightly into deeply swaged or reamed brass, but should not go further than the mouth of the primer pocket. You should not be able to insert the NO GO side using firm hand pressure, if you can, that indicates that the pocket is loose. If it took some pressure to get the NO GO side in, the brass may be good for one more firing depending on your brand of primer, but may fail to hold a primer after that.

You will develop a feel for what level of swage or ream is best for you and your brand of primers. It is best to monitor your swaging periodically, as swage rods do wear out and some systems require adjustment as the rod wears. Dillon swage rods tend to be good for about 15,000-20,000 primer pockets in my experience, for both the 1050 and their standalone swager.

When a swage rod wears out, one symptom is that adding more swage force actually makes the GO side seem tighter. This is due to the worn rod "ploughing" brass rather than swaging it outward.

On the GO side, the edge of the groove is a depth gauge. If the brass has a shallow pocket, this can cause flattening of the primers during seating, but is otherwise not a problem unless extreme. If the brass has a deep pocket, this can cause failure to ignite when hit with the firing pin in some guns.

Small rifle and small pistol are the same depth, and the edge of the groove should either be flush or stick very slightly out when the GO side is inserted fully into a primer pocket. If it sticks out a lot, ensure that the bottom of the primer pocket is free of fired primer residue and try the gauge again.

Large rifle and large pistol have slightly different depth specifications, so the groove on the large gauge is cut so that the shallower edge is the minimum pistol, and the far edge is the maximum rifle. Maximum pistol/Minimum rifle is approximately half way across the gap.

This means that the shallow edge of the groove should be below flush (but still visible) on large rifle brass, and flush to slightly below flush on pistol.

The Swage Gage is good for many thousands of uses if properly cared for. The gage is 0-1 tool steel, a steel similar to that used in many knives. It is not stainless, but the smooth surface finish and alloy will resist corrosion to some extent. Store the gauge lightly oiled and away from moisture, as you would an unblued carbon steel knife. (Wipe off oil from gauge ends before use.) Avoid dropping the gauge onto concrete, as it is a precision instrument and a small dent on the gauge edge can affect its function.