A toolhead that rattles around on a Dillon 650 is a common problem. The cast aluminum toolheads that Dillon sells are somewhat undersized compared to the slot they go into. This up and down play in the toolhead can have several detrimental effects on the consistancy of your reloads.

Variations in full length sizing

Variations in full length sizing are detrimental in several ways. Cases that are not sized enough can fail to chamber, especially if they were fired in a different gun previously. A few thousandths in sizing variation can mean the difference between smooth operation, and a hard-chambering round that is difficult to extract.

Variations in bullet seating depth, crimp and trim.

The loose toolhead will also affect bullet seating depth. When you have a hard sizing case in station 1, the toolhead will flop upward. If there's a case there that doesn't need much or any sizing, it won't flop upward as much. This will cause variations in bullet seating and crimp depth, and unevenness in trim if you have a dillon motor trimmer. This variation can be as much as 3-4 thousandths, enough to seriously affect accuracy.

Variations in powder drop.

The toolhead flopping around will also affect powder drop consistancy. The powder measure will shake, causing the powder to settle into the load bar inconsistantly. As well, the shaking will tend to cause the powder to compress in the hopper, causing loads that start out lower, slowly climb as the hopper settles, and then drop again as the hopper runs low on powder. This variation is usually not serious, but could be as much as 0.2 grains.

So it's bad, how do we fix it?

There are a few options. We sell the UniqueTek

toolhead clamp kit. The way this kit works is two helicoils are inserted into the toolhead retention pin holes on the toolhead itself. Then, instead of putting the drop pins in, you put in tiny hex screws which pull the toolhead upward, tight against the top of the press frame. The screws are smaller than the holes in the frame, so you do not have to modify your press for this, only your toolheads.

So thats the $30 option. There's also another option that costs little to no money and works pretty well, shimming the toolhead. This isn't quite as good as the helicoil screw system, but it's close.

The 50 cent fix

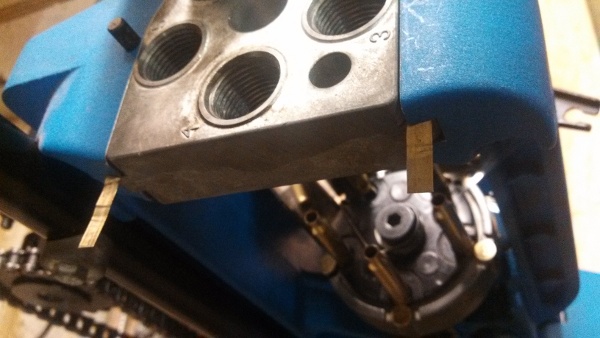

To create brass shims to steady your Dillon 650 toolhead, all you need is a common 5.56 NATO stripper clip, the kind that Lake City ammo comes on. The brass spring inside these stripper clips is the perfect thickness to steady your 650's toolhead. Simply use a punch or a small screwdriver with a hammer to flatten the divots that hold the brass strip in (see illustration at top). Then slide the strip of brass out. Trim the middle part of the brass to slightly smaller than the width as the ears on your 650 toolhead, and the length to about 1.5 inches. Insert the brass as shown in the pictures to the right.

I prefer to place the shims on top of the toolhead so that it is held down. Note that this will likely require adjusting your dies, which are most likely set for the toolhead pushed upward. You can shim the bottom instead, but in my experience, this leads to a slightly angled toolhead which will impart a slight angle to the die in station 4.

What about the precision machined toolheads?

The precision CNC milled toolheads that are available are a good investment, but without a helicoil clamp system, they are still subject to play in the press casting. The play is not as much as with the cast OEM toolheads, but it is still there. I recommend buying the helicoil clamp system to get the most benefit from precision toolheads.

-by Jason Giglio, the Master of Pliers and Wrench Apprentice, 2013-06-03