You are probably thinking that there is no possible way the web needs yet another .223 vs 5.56 article, considering the copious number of them that are out there. The thing is most of them get at least some of the info wrong, spreading even more myths.

CIP is the European version of SAAMI, they define the specifications for cartridges, including maximum pressures. Except that they don't use the same method as SAAMI. SAAMI measures pressure using a piston on top of an intact brass casing (called the "conformal piston" method). CIP uses a hole drilled through the chamber wall and the brass, exposing the sensor to hot gasses directly. NATO (outside the US) uses CIP's method when they define pressures.

When you measure a 5.56 cartridge that rates 55,000 PSI under the SAAMI method using the CIP method, you get somewhere around 62,000 PSI instead. Same cartridge, same pressure, same chamber, just two entirely different methods of reading the pressure. NATO uses the CIP method, so their documents will reflect the higher number, even though the specified pressure is the same.

You can prove this to yourself by checking out MIL-C-9963F and MIL-C-63989A(AR), the older US specification documents for 55gr and 62gr 5.56 NATO ammunition. Both of them specifiy a maximum average pressure of 55,000 PSI, along with the full velocities that 5.56 NATO is rated for. They aren't specifying a reduced power load for our military, they are correctly specfying the unit as measured with a test method similar to SAAMI's.

Another telling piece of evidence is that CIP specifies 62,000 PSI for both 5.56 and 223 remington, measured using their test method. This isn't some case of European ammo being hotter, unlike some calibers, there are no .223 remington antique guns that were not designed for the full pressure.

I don't blame people for getting this wrong. Our brains are trained to think that a PSI is a PSI, and with 5.56 and .223 there are four permutations of cartridge and chamber with 2 different pressure testing methods.

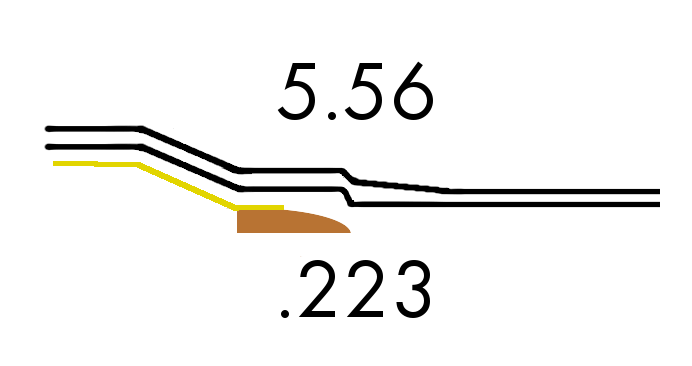

The worst case scenario would be a full power 5.56 load, with a long bullet, fired from a brand-new .223 chamber that was cut to tight dimensions, with very little freebore, fired on a hot day, from brass with a lot of neck tension. Such a tight chamber is common on accurized match bolt-action .223 rifles. In such worst case conditions, pressures above 70,000 PSI have been reported. This is close to the proof pressure for .223, so there is potential danger firing 5.56 from a gun with a .223 chamber.

More typically, 5.56 fired from a .223 chamber exhibits classic signs of overpressure, such as excessive brass flow, expanded primer pockets, cracked case necks, stuck cases, hard extraction, and flattened primers. Since not all .223 chambers are the same, some might show overpressure signs with 5.56 while others may not. All these things happen because the brass is indeed no stronger or thicker in 5.56 than it is in .223. It's rated to take the same 55,000 PSI or so, and that's it.

This is a somewhat dangerous assumption to make, since many .223 chambers do not increase the pressue significantly. I can only assume they specified this way due to a lack of access to a proper 5.56 chambered test barrel, even though reamers to cut the throat of a .223 chamber to 5.56 without changing the headspace are freely available. The manufacturers balked at this request, and in public FBO documents of the question and answer process, you can see where they questioned this specification and were reluctant to fulfill it at first.

Because of this wonky specification method, if you get some of the "FBI load open tip match" 5.56 in surplus, please use it with caution, it is likely overpressure even in a typical 5.56 chamber, and most definitely overpressue in a .223 chamber.

In another example I saw on a forum, someone was going to extrapolate higher loads than recommended, based on a CIP pressure. Their claim was "if it's good enough for Europe it's good enough for me!". Ignorance about differences in CIP vs SAAMI measurements is a dangerous thing.

- LuckyGunner 5.56 vs .223 - Luckygunner did some good pressure testing, discovering that not all .223 cut chambers necessarily increase pressure.

- Ask a Weapons Man: 5.56 vs. .223? WeaponsMan gets all the important bits right, including a note that all these various pressures are actually the same. He cites the US ARDEC case mouth pressures for "NATO", where it's my understanding the "official" NATO method is now the CIP method.